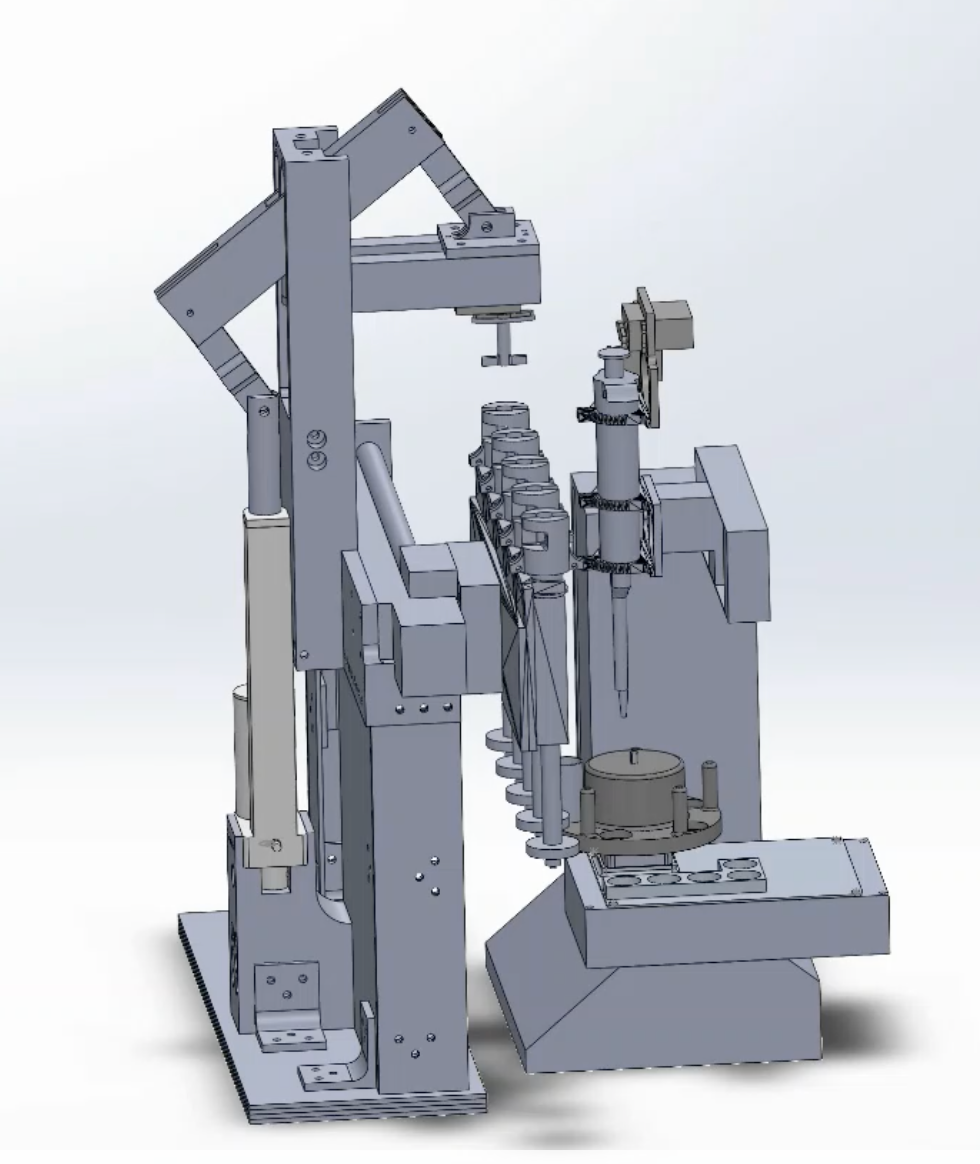

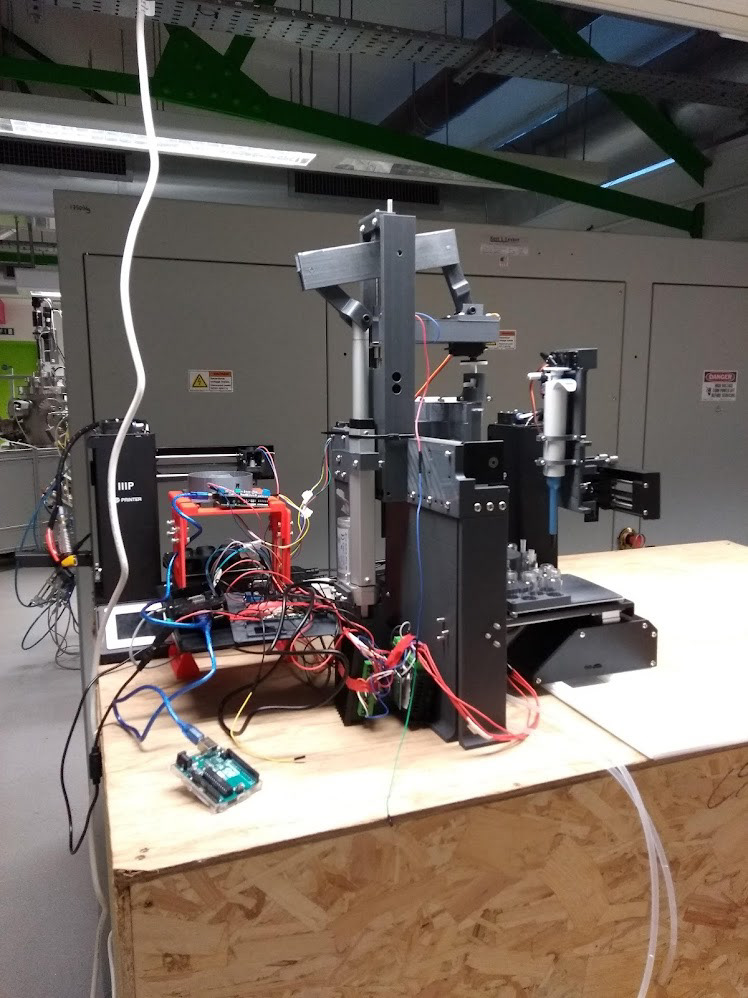

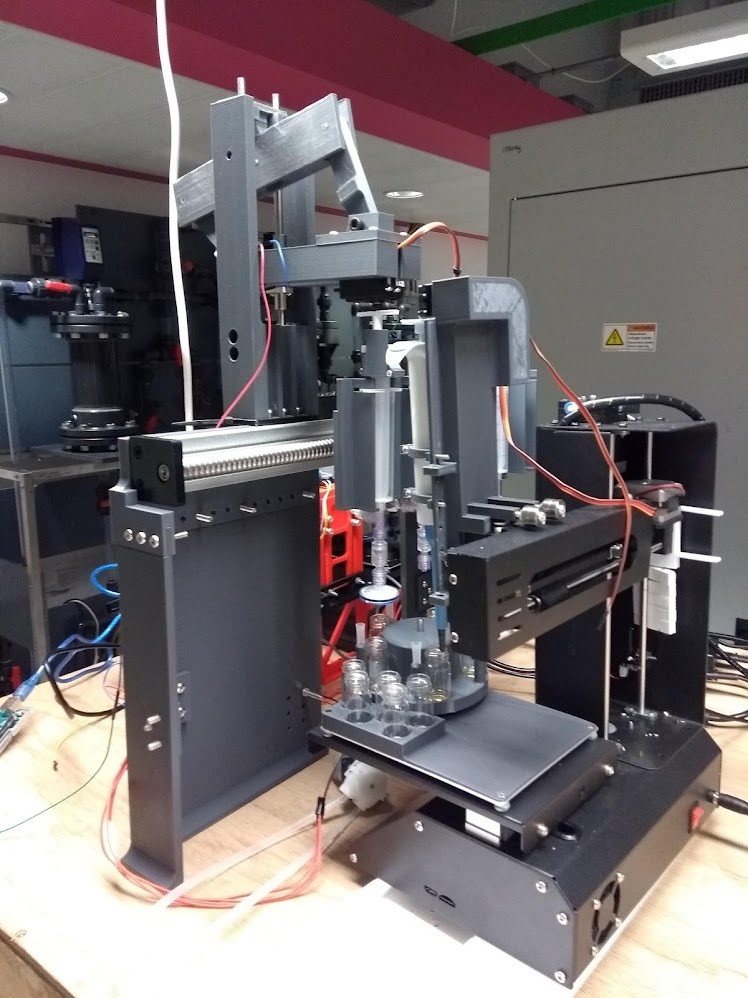

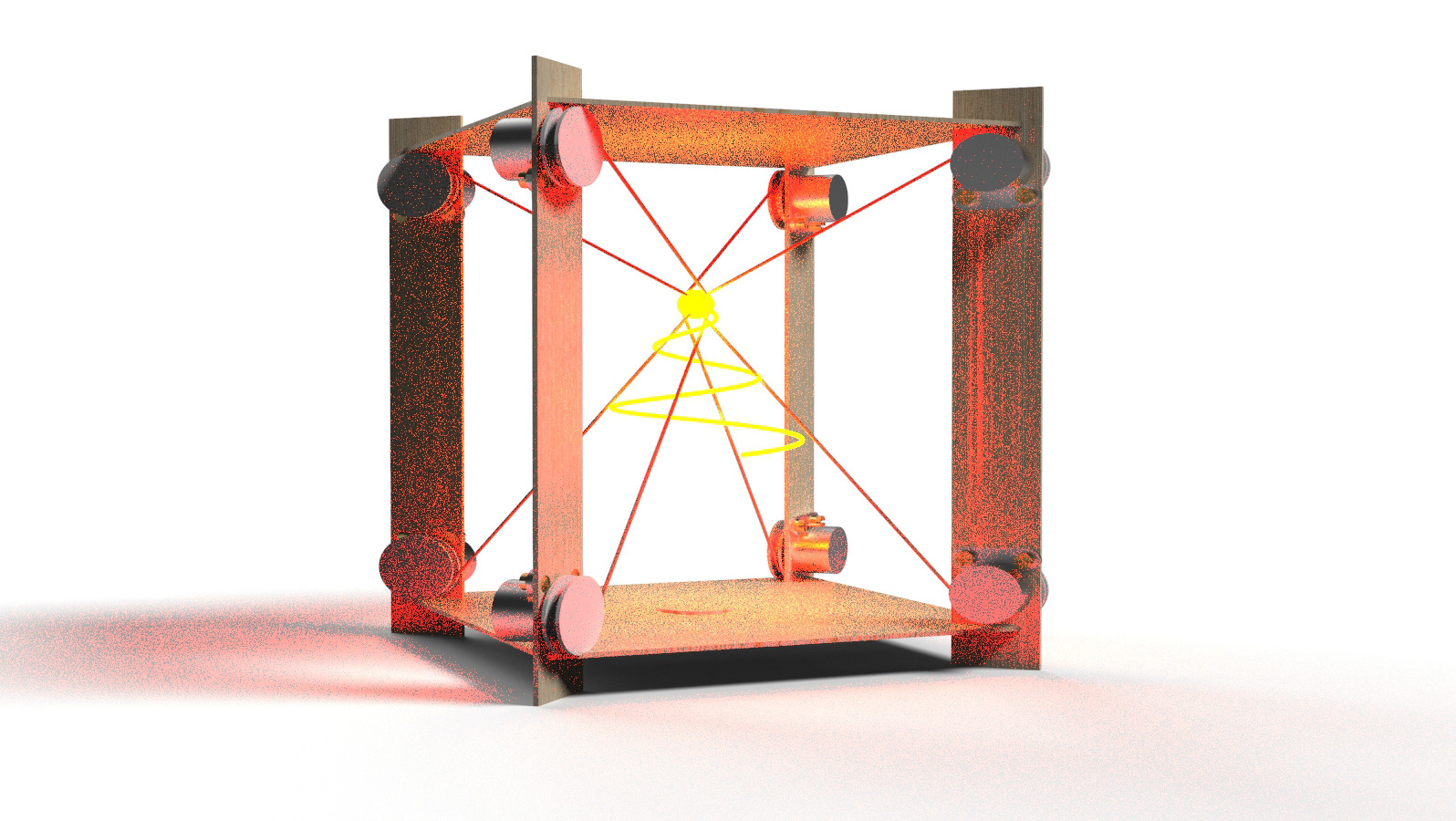

Built a high throughput sampling and cleaning system to allow for discretized sampling of an area to obtain concentration maps of pollutants, using AAS/AES techniques. Repurposed a 3D printer wrote G Code controlling external electronic systems and electronics using Python and Raspberry Pi. Managed the electrical certification of the robot. Allowing studies to pinpoint the origin of pollutants in a fraction of the time, while presenting data in a format that can be overlayed with real-world data.

The aim of the robot is to help identify a solvent that is so effective at dissolving and recovering lead materials from batteries that a process built with it can completely replace smelting-based recycling, which is highly polluting and energy-intensive.

The solvents under investigation are called Deep Eutectic Solvents (DES). They are essentially mixtures of organic compounds that combine unique intermolecular interactions that result in a very chemically active liquid that is highly capable of dissolving metal oxides and other compounds.

The problem with the solvents in the chemical reactions is that they are very viscous. This, combined with their chemistry, means that the reactions are very slow. This firstly presents a challenge because you have to keep the reaction going for a long time (sometimes days!) to get a time-resolved reaction profile. The second challenge is that in these very slow systems, processing parameters significantly affect the final dissolved lead content (how we measure how “good” a solvent is – the more lead dissolved, the better).

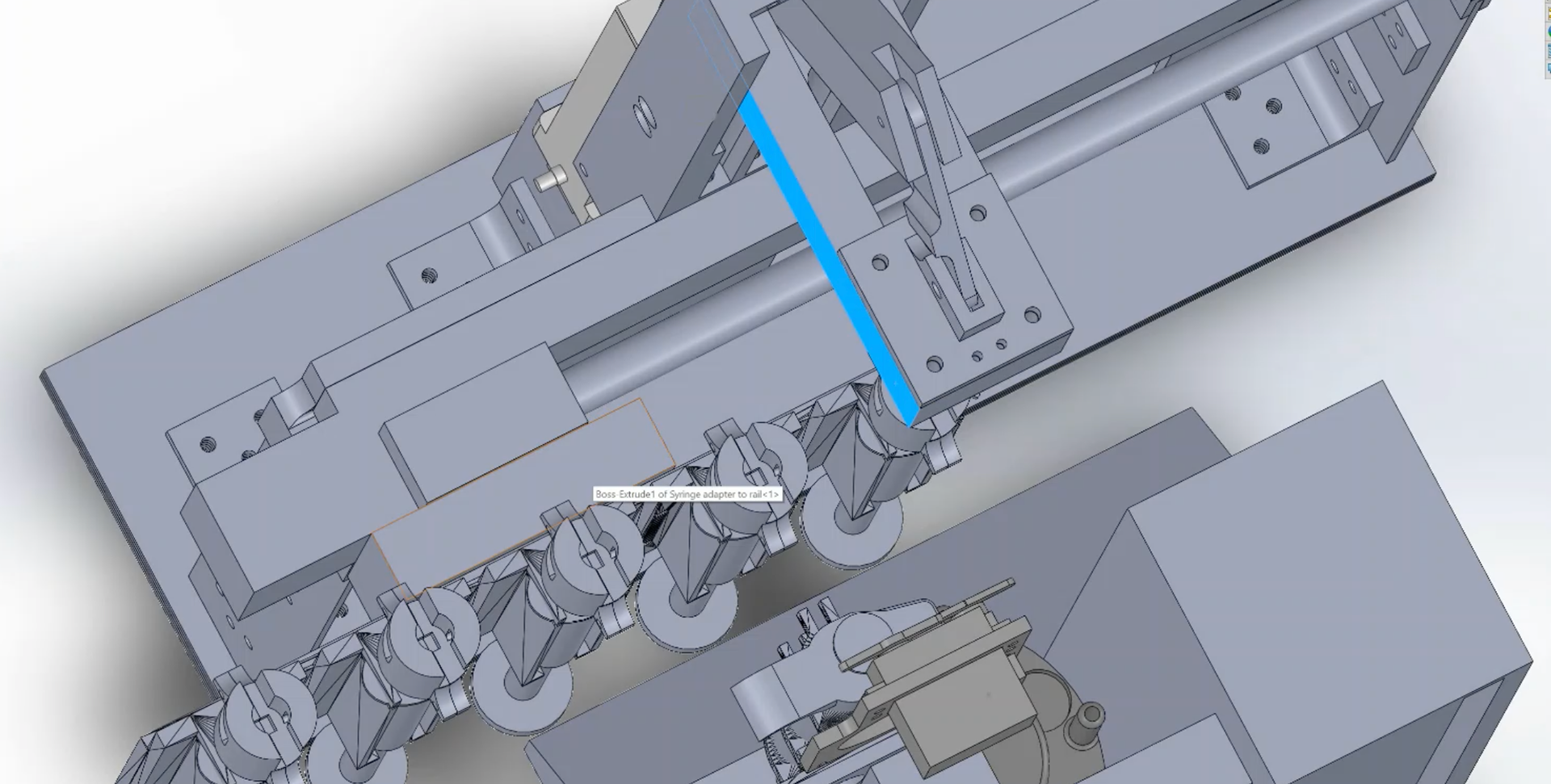

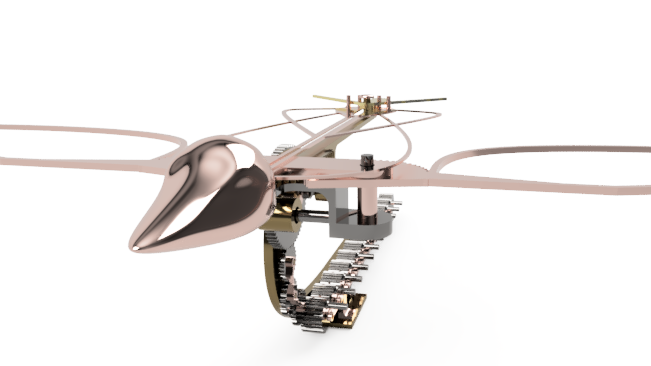

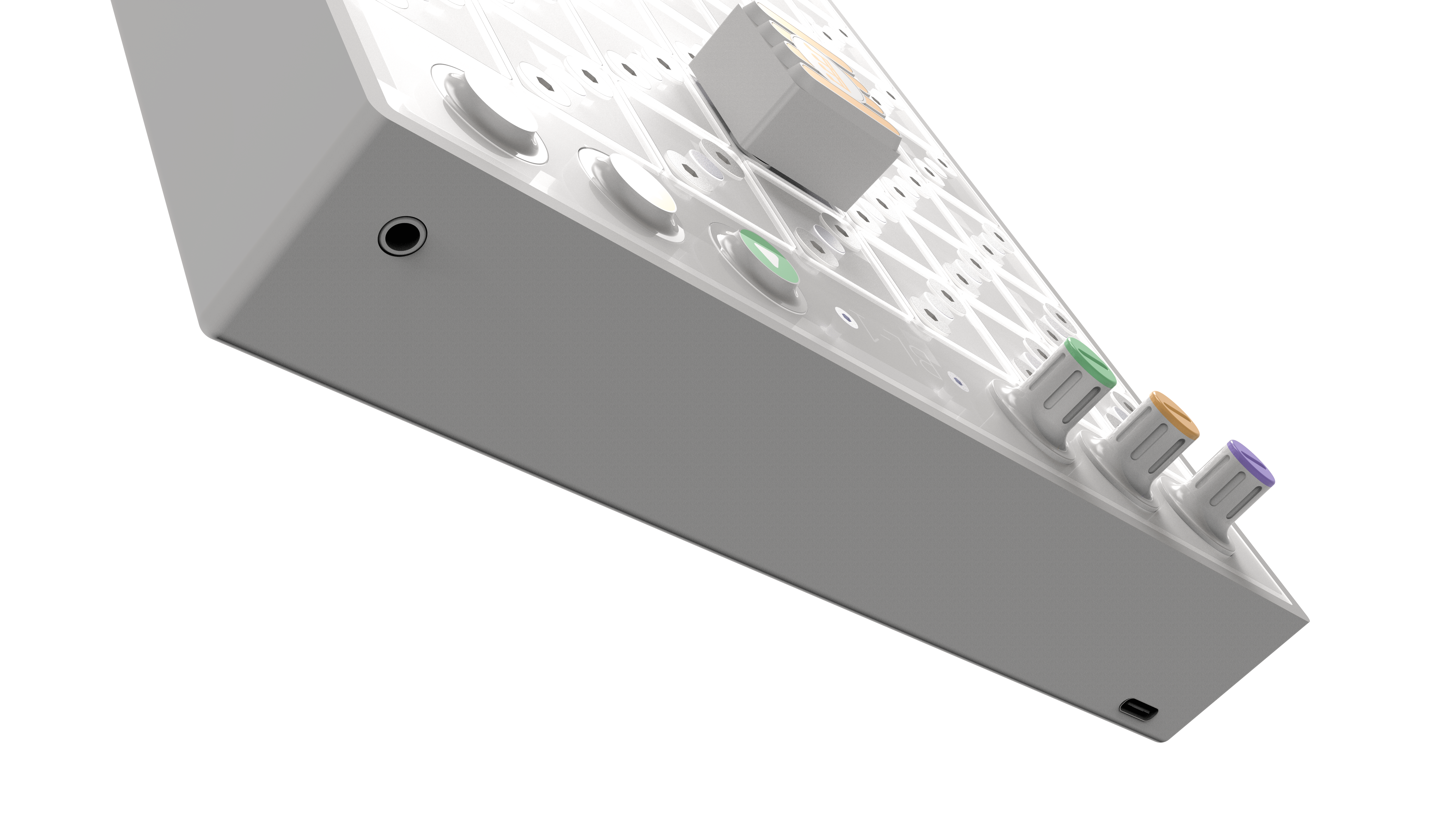

In its current form, the robot will automatically add lead solids to a vial filled with a deep eutectic solvent and stir it for a set amount of time. After mixing, it will automatically extract the mixture of solvents and residual solids into a syringe and then push it through a filter into a smaller vial. A micropipette will then pick up about 20 thousandths of a millilitre and place it in another vial filled with about 5 millilitres of acid. While this machine is a little slower to do the dilutions (400s) than by hand (~300s), it is much more precise and can keep track of the time taken, allowing for more consistency in the result.